Embodied Carbon vs Whole Life Carbon

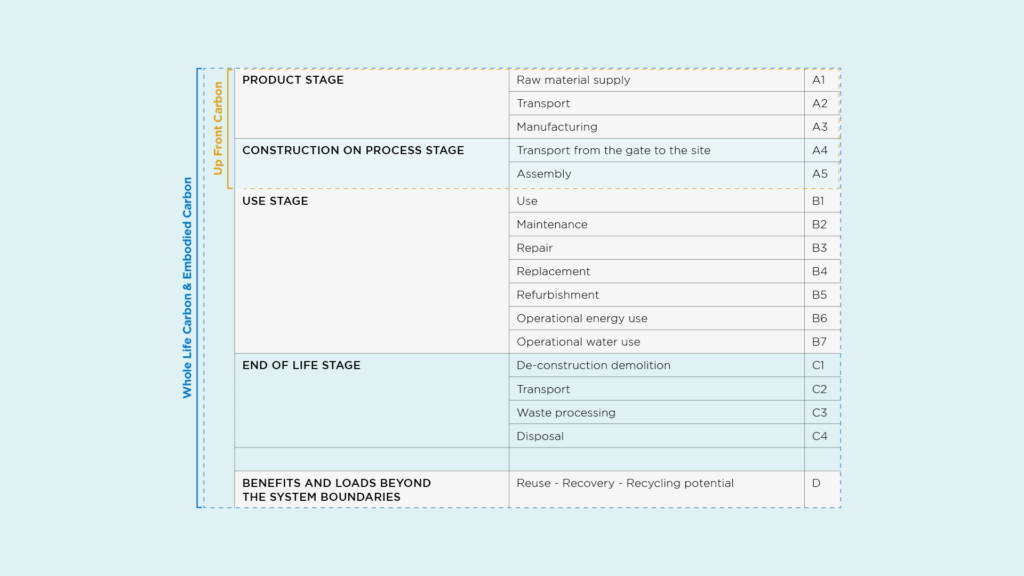

Upfront Carbon

is the emissions associated with the raw material extraction and processing, the energy used by the factory in producing the products, transporting materials to site, and constructing the building. This would encompass life stages A1-A5.

Whole Life Carbon

is the emissions over the whole life cycle of the building. From the extraction of the raw material to create the products to their disposal or reuse at their end of life. All life stages including transport, construction, maintenance and replacements are accounted for in stages A-D.

A material EPD is of little consequence in isolation as it is only when those materials are combined to achieve regulation targets such as thermal U-Values of structural targets that a full specification can be assessed.

For example, the necessity for installing twice the thickness of a particular insulation to achieve regulation potentially increases the carbon contribution two-fold. Also, the other materials used in conjunction with the insulation may need to increase in quantity, further adding to the embodied carbon.

A reduction in fabric performance, e.g. U-Values in a wall may require the inclusion of triple rather than double glazing which would increase the embodied carbon content.

EPDs should be compared only within a Whole Building LCA based on the specification actually used e.g. nZEB, Passive or Future Homes Standard.

Find Out How We are Reducing Embodied Carbon in Construction

Eamonn Clarke, Technical Manager

Talk to Technical

For information and guidance on Environmental Product Declarations (EPDs) and on embodied carbon in construction.

Join our mailing list.

Stay informed of the latest developments with the Unilin Insulation mailing list

"*" indicates required fields

Resources

Have a look at our brochures, technical files and other documents